Coffee : small-scale processing

Practical Action

producing a good product. There are basically two types of grinders - manual grinders and

motorized grinders.

Manual grinding mills An experienced operator can grind about 20kg in an eight hour day.

However, this is hard and tedious work. The grinding mills need to be set so that they produce

the desired degree of fineness of ground product which satisfies the end-user. For small-

scale production (up to 100kg/day) a series of these grinders is all that is needed. Motorised

grinders are available for larger scale production units.

Motorised grinding mills Horizontal plate, vertical plate or hammer mills are suitable for

grinding coffee. A grinding mill has to be placed in a separate and well-ventilated room

because of the fine particles of coffee dust generated during milling. These particles can be

an irritant.

Instant coffee

To produce an instant coffee, the soluble coffee solid and volatile compounds have to be

extracted and then dried into a powder or granules. The production of instant coffee is

unsuitable for small-scale enterprises as it requires expensive machinery such as an extractor

and a freeze- or spray-drier. However a general description is provided below.

Prestripping Sometimes the volatile compounds in coffee (of which there are over 700) are

removed before the extraction of soluble coffee solids. This is usually done by passing steam

through a bed of ground and roast coffee.

The initial steam pressure has to be high

enough for the steam to pass through a static

bed of coffee. The extracts and steam are

condensed to give a mixture of water and

volatile compounds. These compounds can be

condensed and collected using a tubular

condenser with chilled water flowing through

it.

Extraction of soluble coffee solids The

extraction of soluble coffee solids is usually

done using water as the solvent. Extraction is

continued until the solution obtained is

15-25% w/w coffee extract. The extraction is

usually done at 175ºC since at 100ºC the

extracted solids are difficult to dry. There are

three ways the solids can be extracted.

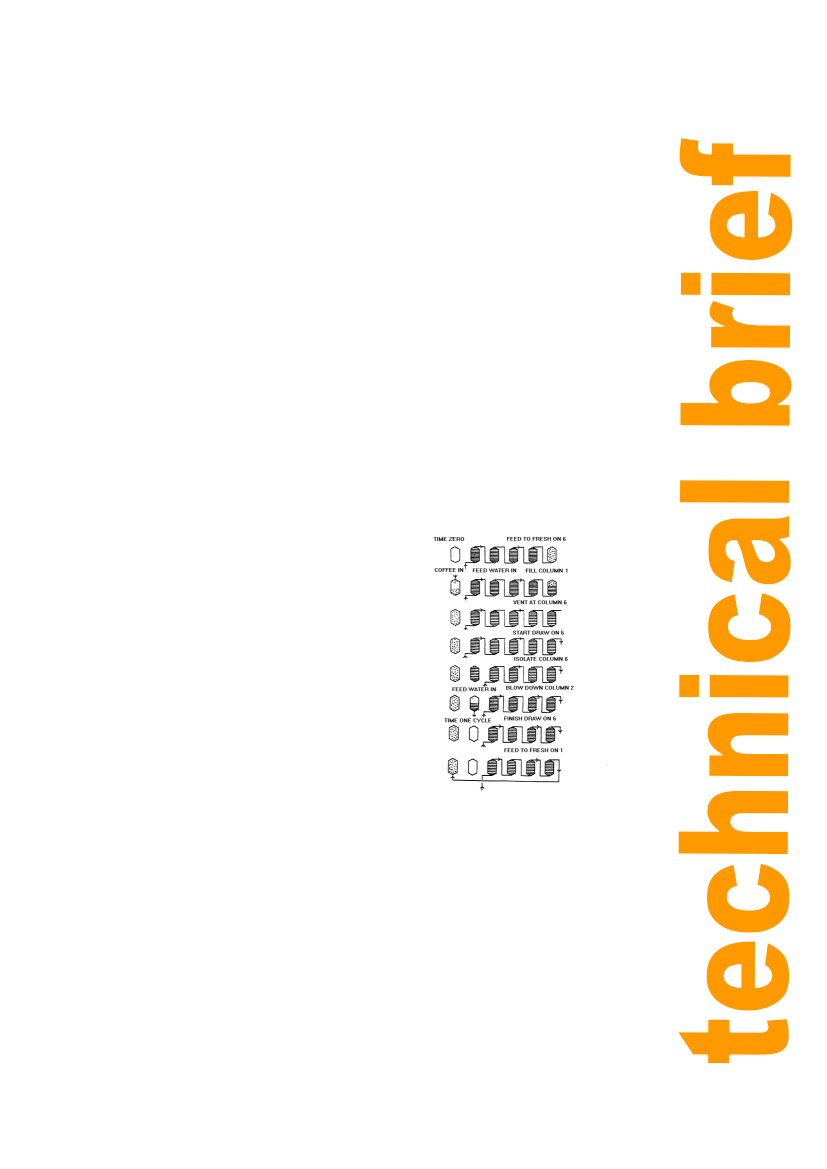

Percolation batteries This is the most

common method. The roasted and ground

Figure 4 : Percolation batteries

coffee is held in a series of 5-8 vessels. Hot

water is passed through the vessels and, when the soluble coffee solids have been fully

extracted from each vessel, it is isolated from the battery and spent coffee discharged. A new

vessel replaces this exhausted vessel (see Figure 4). As the extraction takes place at 175ºC,

the system needs to be under pressure. A solution of 15-25% w/w of soluble material is

produced which can then be dried.

Countercurrent system Coffee is fed continuously into the bottom of an inclined cylindrical

vessel and moved upwards by two helicoidal screws rotating at 10-22 revolutions per hour.

Hot water enters the top and the extracted solids in solution exit at the bottom. The vessel is

pressurised and kept at 180ºC by the use of temperature jackets.

Slurry extraction Coffee and water are agitated together in a tank and separated using a

4